The 4-day FBC China International Window & Curtain Wall Expo has successfully ended in Shanghai Hongqiao National Convention & Exhibition Center on August 6th, 2023!

The equipment ”laser sawing and milling intelligent workstation” brought by CGMA made an amazing appearance at the exhibition and attracted a lot of attention.

The equipment of our booth attracted many customers to visit and conducted further negotiations.

One piece of equipment can meet cutting + front drilling and milling/laser engraving + up and down drilling and milling + post laser cutting/laser engraving. Industry-leading technology and broad market prospects have won the favor and recognition of many audiences.

Product Introduction 1. Mainly used for cutting of industrial aluminum, aluminum curtain wall profiles and window profiles,also can cutting uPVC profiles. 2. The worktable and saw blade can be adjustable any angles. 3. Adopted carbide saw blades, the outer diameter can reach out 650mm, with high linear speed,with high processing accuracy. 4. This machine adopts Britain TRIO controller,the worktable arbitrary rotation and saw blade arbitrary swing angle CNC system,increase 4KW…

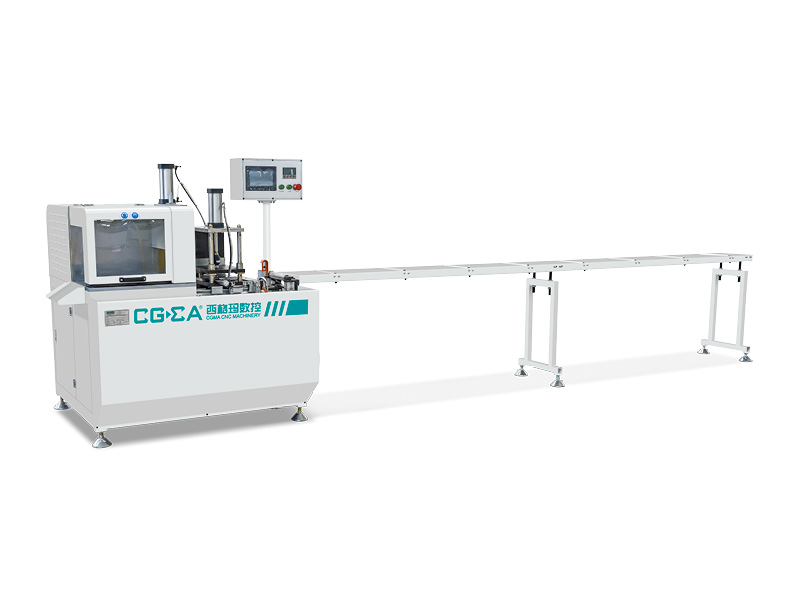

了解更多Product Introduction Main Function: 1. It is suitable for processing mounting holes, water slots, lock holes, and shaped holes of various aluminum profiles. 2. All holes and grooves on the same processing surface can be processed in one clamping operation, which has extremely high working efficiency. 3. Workbench: Movable workbench; pneumatic clamping, workbench height 800mm from the ground. 4. Equipped with 6-station mobile rotary tool magazine and automatic tool change….

了解更多Product Introduction 1. Mainly used for cutting of industrial aluminum, aluminum curtain wall profiles and window profiles,also can cutting uPVC profiles. 2. The worktable and saw blade can be adjustable any angles. 3. Adopted carbide saw blades, the outer diameter can reach out 650mm, with high linear speed,with high processing accuracy. 4. This machine adopts Britain TRIO controller,the worktable arbitrary rotation and saw blade arbitrary swing angle CNC system,increase 4KW…

了解更多Product Introduction 1.This machine is a heavy duty hydraulic punching machine which is widely used for aluminium PV / solar panel framework manufacturing. 2.The punching machine equipped with high speed hydraulic station and two hydraulic cylinders which working synchronous to effect whole length of profiles punching at same time. 3.The air cooling system can reduce the hydraulic station working temperature. 4.The punching dies fixed on bed and easily adjust the distance…

了解更多Product Introduction 1.It’s a heavy duty hydraulic punching machine which is widely used for aluminium PV / solar panel framework manufacturing. 2.The punching machine equipped with high speed hydraulic station and two hydraulic cylinders which working synchronous to effect whole length of profiles punching at same time. 3.The air cooling system can reduce the hydraulic station working temperature. 4.The punching dies fixed on bed and easily adjust the distance according to real…

了解更多Main feature 1. High accuracy positioning: adopts servo motor drive, the ball screw drive feeding and fix the position. 2. Large cutting range: the cutting length range is 3mm~600mm, the width is 130mm, the height is 230mm. 3. Feeding stability: special feeding clamping manipulator, the corner connector is not contact with cutting vertical panel during feeding, so as to prevent the cutting surface meet the saw bit, ensure the feeding accuracy. 4. Big…

了解更多Main feature 1. High accuracy positioning: the movable saw head adopts servo motor drive the gear, to drive the fixed ruler on the precision screw rack. 2. Large cutting range: the cutting length range is 500mm~5000mm, the width is 125mm, the height is 200mm. 3. Big power: equipped with 3KW direct-connected motor, the efficiency of cutting profile with insulation material is improved 30% than 2.2KW motor. 4. Stable cutting: the…

了解更多Product Introduction 1.The production line features low power consumption, low noise and scrap automatic collection, which can be used to process profiles with film and non-film as well. 2.It can finish the length cutting at the cutting saw station, flushing holes, installation holes and grounding marks punching by a combination mold in one step at punching station, automatic insert the corner key and riveting at both end at the last…

了解更多Product Introduction 1.The production line features low power consumption, low noise and scrap automatic collection, which can be used to process profiles with film and non-film as well. 2.It can finish the length cutting at the cutting saw station, flushing holes, installation holes and grounding marks punching by a combination mold in one step at punching station, riveting points punching at both end at the last step. 3.The production line…

了解更多Main feature: 1.Equipped with 3KW motor to drive the mechanical spindle rotation through belt driving. 2.It adopts servo motor drive, the ball screw drive feeding and fix the position, the accuracy of positioning is high. 3.The cutting speed is very fast, the rotation speed of the saw blade can up to 3200r/min, and cut two profiles at the same time. 4.The cutting range: cutting length is 3mm~300mm, cutting width is…

了解更多Post time: Aug-15-2023