Product Introduction

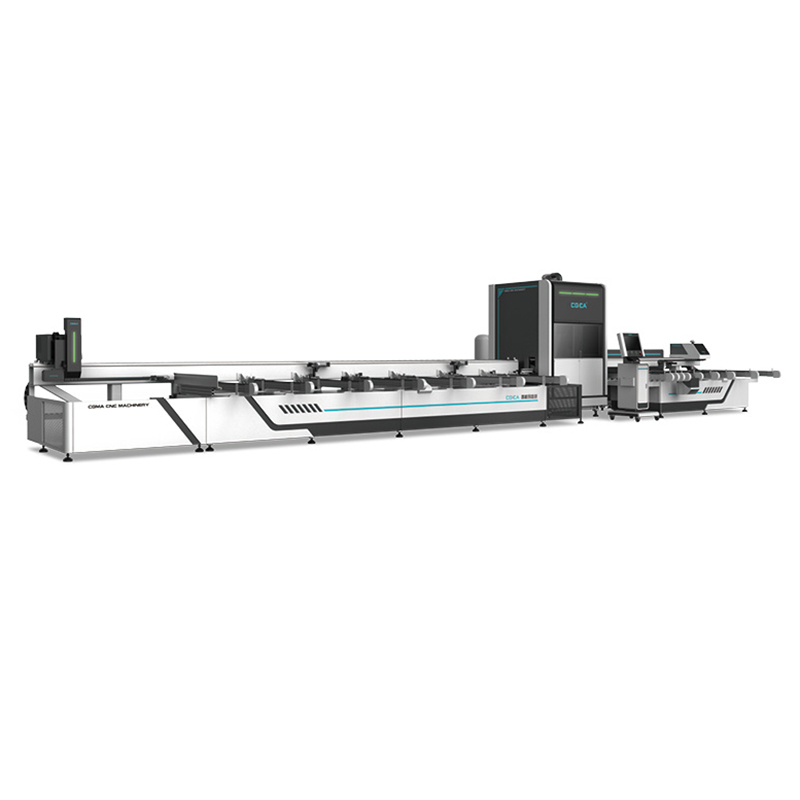

This machine is used for cutting aluminum profiles in angle 45°, which is composed of three parts, feeding unit, cutting unit and unloading unit.

Mechanical arm is driven by servo motor, which can automatically adjust the position .It can put 7 Pieces of profiles on feeding conveyor table at the same time.

Mono-block casting type of main engine base and cutting mechanism, and the cutting bin is enclosed totally to operate, more safe, environmental protection and low noise. Equipped with 3KW direct-connected motor, the efficiency of cutting profile with insulation material is improved 30% than 2.2KW motor.

The saw blade is separated with the cutting surface when returns, to avoid sweeping the profile, improve the cutting surface finish, avoid burrs, and the service life of saw blade can be increased more than 300%. Equipped with auto scrap collector which is set on the side of the main engine, the wast scraps are transported to wast container by conveyor belt, reduce cleaning frequency and improve work efficiency, saving space, and maintenance convenient. It is also equipped with a cod bar printer, it can print the material identification in real time, very convenient.

Product Details

Main Feature

1.Highly automatic: fully automatic feeding, cutting and unloading.

2.High efficiency: cutting speed 15-18s/pcs (average speed).

3.Large cutting range: cutting length range is 300mm-6800mm.

4.High cutting finish and high service life of saw blade.

5.Remote service function:improve the service efficiency, reduce downtime.

6.Simple operation: Only need one worker to operate, easy to understand and learn.

7.Online with ERP software, and import the processing date directly through network or USB disk.

Main Technical Parameter

|

Item |

Content |

Parameter |

|

1 |

Input source | AC380V/50HZ |

|

2 |

Working pressure | 0.5~0.8MPa |

|

3 |

Air consumption | 200L/min |

|

4 |

Total power | 17KW |

|

5 |

Cutting motor | 3KW 2800r/min |

|

6 |

Saw blade specification | φ500×φ30×4.4 Z=108 |

|

7 |

Cutting section size(W×H) | 90°:130×150mm、45°:110×150mm |

|

8 |

Cutting angle | 45° |

|

9 |

Cutting accuracy | Cutting accuracy:±0.15mmCutting perpendicularity:±0.1mm Cutting angle:5' |

|

10 |

Cutting length | 300mm~6500mm |

|

11 |

Dimension(L×W×H) | 15500×5000×2500mm |

|

12 |

Weight | 6300Kg |

Main Component Description

|

Item |

Name |

Brand |

Remark |

|

1 |

Servo motor,servo driver |

Schneider |

France brand |

|

2 |

PLC |

Schneider |

France brand |

|

3 |

Low-voltage circuit break,AC contactor |

Siemens |

Germany brand |

|

4 |

Button, Knob |

Schneider |

France brand |

|

5 |

Proximity switch |

Schneider |

France brand |

|

6 |

Photoelectric switch |

Panasonic |

Japan brand |

|

7 |

Cutting motor |

Shenyi |

China brand |

|

8 |

Air cylinder |

Airtac |

Taiwan brand |

|

9 |

Solenoid valve |

Airtac |

Taiwan brand |

|

10 |

Oil-water separator(filter) |

Airtac |

Taiwan brand |

|

11 |

Ball screw |

PMI |

Taiwan brand |

|

12 |

Linear guide rail |

HIWIN/Airtac |

Taiwan brand |

|

13 |

Diamond saw blade |

KWS |

China brand |

| Remark:when the supply is insufficient, we will choose other brands with the same quality and grade. | |||

-

Single-head corner crimping machine for aluminu...

-

3+2 Axis CNC End Milling Machine for Aluminum P...

-

CNC Drilling and Milling Machine Center for Alu...

-

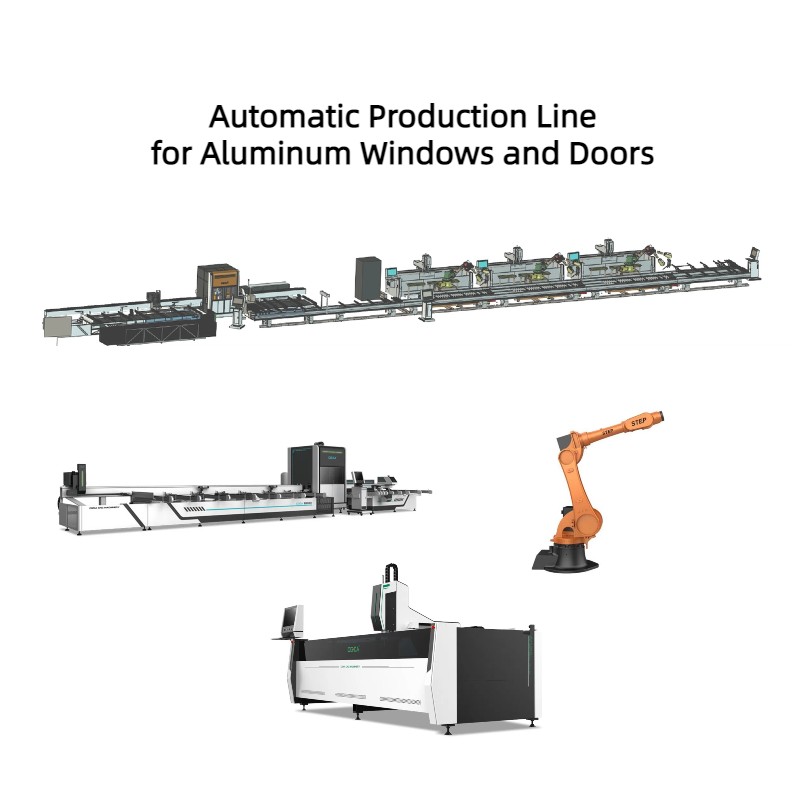

Automatic Intelligent Production Line for Alumi...

-

CNS Double Head Precision Cutting Saw for Alumi...

-

CNC Vertical Four-head Corner Crimping Machine ...