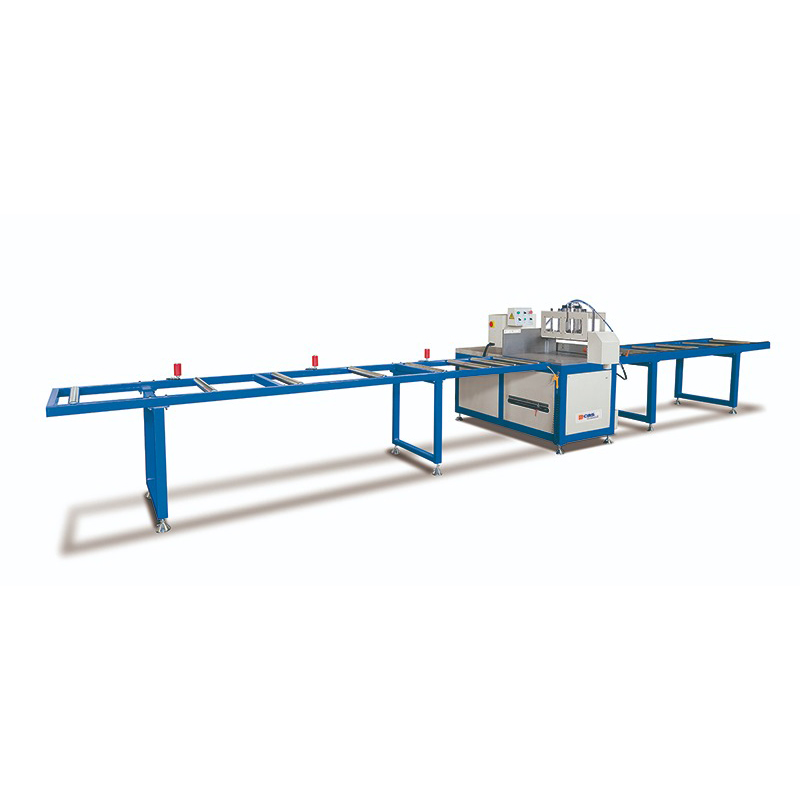

Product Introduction

1.The machine body is heat treated to eliminate internal stress and has sufficient strength and rigidity.

2.The machine adopt high quality hydraulic station driven, the four-bar linkage mechanism ensures that the slider and the punching pins are simultaneously working.

3. The punching stroke adopts photoelectric control, which is easy to operate and has high precision.

4.The punching pins is free of disassembly, so, the holes distance is easily set without disassembling the punching pins, which features high production efficiency and easy operate.

5.The machine have special support system to guide the punching pin to make sure the pins in the center of the core, the punching is free of burrs, and the service life of the punching pins can be extended to 4-6 months.

6.The hydraulic system adopts the latest 40 valve group, increased the pressure-retaining valve and quick valve, improve production efficiency, punching time only 6S.

7.The hydraulic system adopts an integrated design to save space. The use of an adjustable vane pump instead of a traditional plunger pump reduces equipment operating noise.

8.The hydraulic system has three levels of protection, the main system pressure protection, adjustable electric contact pressure gauge and travel limitation protection.

9.It adopts self-lubricating copper sleeve and automatic oil filling system also, the time can be adjusted easily.

Main Technical Parameter

|

No. |

Content |

Parameter |

|

1 |

Input voltage | 3-phase, 380/415v, 50hz |

|

2 |

Rated power | 25kW |

|

3 |

Punch stroke | 75mm |

|

4 |

Working pressure | 18MPa |

|

5 |

Max. Pressure | 25MPa |

|

6 |

Max. Punching Holes | 60 nos. |

|

7 |

Punching holes distance | 50mm |

|

8 |

Punching holes diameter | 16.5+0.2/-0.0mm |

|

9 |

Punching time | 6S |

|

10 |

Worktable length | 3000mm |

|

11 |

Worktable height | 950mm |

|

12 |

Overall dimensions | 3700x1200x2350 mm |

|

13 |

Gross weight | 9500kg |

Product Details